Capablities

FinoMag Magnetics is an innovative designer and manufacturer of custom permanent magnet,custom magnet assembly.Our company processes everything in this area, from Neodymium magnet raw material to exquisite magnet separator lines.Our manufacturing own the most advanced technologies and a wide range of processing equipment.

We are impeccable with the equipment maintenance, work at a 100% capacity and provide satisfaction for each project. Our team includes

experienced R&D and QA engineers who deliver 2D and 3D simulations. They are used to determine the optimum custom magnet product for each specific need.We provided custom magnetic solutions for the electronic,automotive, aerospace, medical and green power industries.

Permanent Magnet

With a full & complete magnet production line,we offer a comprehensive magnet solutions to customers and assist customers to select the right material.- Material Research

- Analysis

- Prototyping

- Magnet Production

- Electroplating

- Magnetizing

- Testing

Magnet Assemblies

Our team have good experience to assemble and develop from mirco to large magnet assembly design, Keeping customers satisfied with our product or service is the business goal- Concept Design

- Simulation

- Lamination

- Possibilty Analysis

- Pre-launch

- Manufacturing

- Automatic Assembling

Design&engineer

The technical team enhance the capacity and possibility at product development and improvement,various tailored-design made in our R&D dept.- Mechanical&Electric

- Engineering

- 3D Design Software

- Metal &Plastic Tooling

- Make

- Flexible design

- modification

- Aging testing

Fast Prototyping

No one like to wait for long time prototyping as new project start, but it’s hard to find the existing components from the inventory,we could do better to meet any emergency- Prototyping management system

- Sourcing specialist

- 3D PRINT Service

- CNC Processing

- Surface treatment

- processing

Machine Processing

The high accuracy machining work bring a big advantage at the magnets and other material machine processing, enable us to meet required shapes and manufacture close tolerance components- Muti-lines Linear cutting

- Drilling Machine

- Milling Machine

- CNC Processing Center

- TIG & Laser welding

- Laser Metal Cutting

- Automatic plastic injection

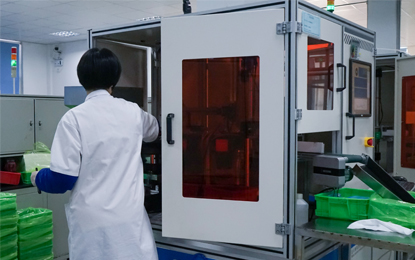

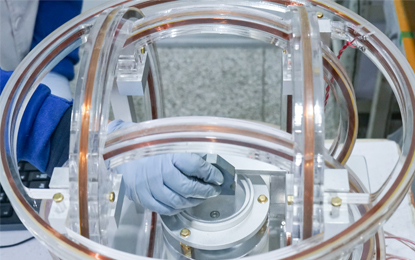

Testing&inspection

Quality is the core of the manufacturer,the testing and inspection work are strictly executing ISO standard,control the whole production process from raw materials ‘quality to other aspects to improve.- Hysteresis Graph Test System

- Vibrating Sample

- Magnetometer

- Intelligent Digital Gauss

- Meter / Tesla Meter

- Fluxmeter

- Helmholtz Coils

- Electronic measurement devices

- Salt Spray Test

- PCT Test process

- HAST TESTER

DOWNLOAD A COMPLETE CATALOG OF OUR SERVICES AND PROJECTS SPECIFICATIONS

Download